One of the things about making outerwear is having the ability to customize. Want a purple ski jacket? You can do it. Want a jacket with a ‘poachers pocket’ in the back? No problems. Want a jacket with vertical chest pockets with zippers so that you can put a bottle of penicillin and keep it warm if you have to doctor sheep out in the barn in January and it’s 0 degrees F out there? Yep. You can do that too (speaking of which, I used to have a lovely jacket from Woolrich, unfortunately colored pink, which ended up as a barn coat for precisely that reason. Trying to draw liquid antibiotics out of a bottle through a rubber stopper with a syringe when it is under 30 degrees is like trying to suck roast beef through a straw and no, we don’t use antibiotics with our livestock anymore).

One of the things about making outerwear is having the ability to customize. Want a purple ski jacket? You can do it. Want a jacket with a ‘poachers pocket’ in the back? No problems. Want a jacket with vertical chest pockets with zippers so that you can put a bottle of penicillin and keep it warm if you have to doctor sheep out in the barn in January and it’s 0 degrees F out there? Yep. You can do that too (speaking of which, I used to have a lovely jacket from Woolrich, unfortunately colored pink, which ended up as a barn coat for precisely that reason. Trying to draw liquid antibiotics out of a bottle through a rubber stopper with a syringe when it is under 30 degrees is like trying to suck roast beef through a straw and no, we don’t use antibiotics with our livestock anymore).

Lack of pockets in outerwear is probably the number one complaint people have with ready to wear offerings. Pockets are an extra step – they literally cost money, so manufacturers put in only what they absolutely have to and usually put them either as patch pockets or as in-seam pockets because those are simpler and have fewer steps so they are cheaper to manufacture.

One of the issues with putting in pockets into outerwear that you are making is that you have really have to think through the following questions:

1. Who is using this garment?

2. Why do they need pockets? What are they going to use them for? What utility are they providing?

3. How many of them do they need?

4. Where do they need them to be located on the garment?

To answer the questions for this raincoat —

Who is using it? My almost-three-years-old grandson

Why do they need pockets? Well, knowing him, he’ll want to put rocks in them. These are not ‘hand-warmer’ pockets.

How many of them do they need? Well, two should work for him

Where do they need them to be located? On the front works best for him; if I put them as ‘in-seam’ pockets, anything like a rock will probably get missed.

Not that I want to encourage him to put rocks in them, mind you – this fabric is not exactly heavy weight — so I’m keeping that ‘let’s not make rock picking convenient’ factor in mind.

When you are putting in pockets in a garment that either has to keep the cold or rain OUT, you want to keep the rain out of the pockets, too. Nothing worse than finding wet hats and gloves in a pocket later, or a salamander in residence. How do we do that? Well, flaps are a good first answer, but you need something that will keep the flap closed. Zippers are a good choice in items that you want to keep snow out of, and there are always snaps or buttons, but for this particular item, I’m going with a Velcro(tm) product which will be easy for my grandson to open but will also keep dirt, rain and things OUT.

So, I need a pocket and I need a flap to go over the top of the pocket and I need to install the fastening ‘system’ on the top of the pocket and on the inside of the flap.

Step one: The Pocket

Step two: Cutting out and stabilizing The closing flap really is the part which needs a lot of stabilitizing, since that, literally is the ‘point of failure’ on many pockets, so I not only cut out the DWR fabric for the flap, I interlined it with cotton muslin to stabilize it. I could have also used a sew-in interfacing. I then folded the muslin stabilizer and the flap in half; right side to right side and sewed down the short vertical edges, trimmed the seams and poked out the corners, turned the flaps right side out and top-stitched the edges down. I also zigzagged the long horizontal unfinished edge. Again, as your Aunty has reminded you before: You can’t press this stuff with a hot iron because it will melt. I also made the pocket with it’s stabilizing flap at the top.

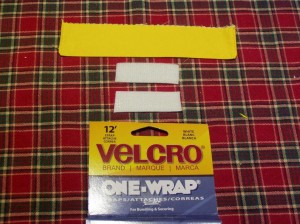

Step three: Applying the fastening system What I’m using here is not the standard Velcro(tm) system of one tape with hooks/one tape with loops. This is an everything in one tape – one side has little hooks and the other side is fuzzy, which for little hands is easier to open and close. I marked the centers on the top edge of the pocket and for the closing flap in the inside and also on the pieces of Velcro(tm).

What I’m using here is not the standard Velcro(tm) system of one tape with hooks/one tape with loops. This is an everything in one tape – one side has little hooks and the other side is fuzzy, which for little hands is easier to open and close. I marked the centers on the top edge of the pocket and for the closing flap in the inside and also on the pieces of Velcro(tm).

I sewed the hook side out side on the underside of the closing flap, close to the edge. To get the ‘sweet spot’ for the fuzzy side up on the pocket itself, check the photo above. Put the closing flap, Velcro(tm) side facing you. Lay the pocket,centering it on the flap, right side up, as indicated in the photo. Attach the fuzzy side of the Velcro(tm) on the hook side on the flap and then carefully, fold down the flap toward the pocket until it touches the top of the pocket. Grab one edge of the fuzzy side of the Velcro(tm) and pull down onto the pocket to secure it with your fingers. Straighten it out, parallel with the top edge of the pocket and then machine sew it down all the way around.

I sewed the hook side out side on the underside of the closing flap, close to the edge. To get the ‘sweet spot’ for the fuzzy side up on the pocket itself, check the photo above. Put the closing flap, Velcro(tm) side facing you. Lay the pocket,centering it on the flap, right side up, as indicated in the photo. Attach the fuzzy side of the Velcro(tm) on the hook side on the flap and then carefully, fold down the flap toward the pocket until it touches the top of the pocket. Grab one edge of the fuzzy side of the Velcro(tm) and pull down onto the pocket to secure it with your fingers. Straighten it out, parallel with the top edge of the pocket and then machine sew it down all the way around.

Step three: Installing the flap and the pocket. Now, as you may recall, I marked, in pen, on the inside of the fronts of the raincoat, the spots for the pockets. Because this fabric is rather thin, I could see those marks from the front; if you can’t see your marks, you need to take out your pattern, make holes where the marks are and using something like a pen, transfer the marks to the fronts. Center the pocket closing flaps on those and sew them down to the outside of the coat fronts.

Step three: Installing the flap and the pocket. Now, as you may recall, I marked, in pen, on the inside of the fronts of the raincoat, the spots for the pockets. Because this fabric is rather thin, I could see those marks from the front; if you can’t see your marks, you need to take out your pattern, make holes where the marks are and using something like a pen, transfer the marks to the fronts. Center the pocket closing flaps on those and sew them down to the outside of the coat fronts.

To get the right location for the pockets themselves, see the photo. The pocket is flipped up, Velcro(tm) up. Take your finished pocket and apply it, Velcro(tm) side down, to the flap. Then flip the entre unit down so that the pocket is now right side facing you. Use something other than pins to secure it to the outside of the coat front (something like 3M hair tape works really well for this). Then carefully open up the flap so that it’s out of your way. Sew down the pocket, all the way around, using zigzag bar tacks at the upper corners.

To get the right location for the pockets themselves, see the photo. The pocket is flipped up, Velcro(tm) up. Take your finished pocket and apply it, Velcro(tm) side down, to the flap. Then flip the entre unit down so that the pocket is now right side facing you. Use something other than pins to secure it to the outside of the coat front (something like 3M hair tape works really well for this). Then carefully open up the flap so that it’s out of your way. Sew down the pocket, all the way around, using zigzag bar tacks at the upper corners.

Step four: Finishing up. At this point, you now need to waterproof the inside of the coat front where you’ve sewn on the pockets – we made a whole line of holes there and need to put on seam sealing tape there. It’s a lot easier to do this NOW rather than later when I will have a lining and zippers and so on to contend with so off to the ironing board I go.

And this is how this looks when I’m done. I’ve got the underside flipped up so that you can see the seam sealing tape as well as the outside of the pocket and the flap.

And this is how this looks when I’m done. I’ve got the underside flipped up so that you can see the seam sealing tape as well as the outside of the pocket and the flap.